Application Analysis of Micro Pumps in Various Industrial Printers

2023-11-06

With the continuous progress of technology, various types of industry printers have significantly improved in meeting diverse needs. Micro pumps, as a crucial liquid delivery device, play an essential role in various printers.

1. Diaphragm Pump

Diaphragm pumps use the bending of a diaphragm to drive fluid transfer, and their precision and controllability make them ideal choice for inkjet printers. Among all types of printers, inkjet printer is one of the most common applications. The role of the diaphragm pump in inkjet printers mainly includes the following aspects:

·Ink delivery: The diaphragm pump delivers ink from the ink cartridge to the print head, ensuring precise ink ejection during the printing process, resulting in clear images and text.

·Flow control: The precise control capability of the diaphragm pump can ensure that every drop of ink is sprayed onto the paper as needed, thereby providing high-quality printing.

·Quick response: The diaphragm pump can start or stop ink delivery in an instant, adapting to the needs of high-speed printing.

·Easy maintenance: The structure of the diaphragm liquid pump is relatively simple and easy to be maintained and replaced, which helps the printer have a longer service life.

TOPSFLO TF30A-C diaphragm liquid pump

2. Gear Pump

Gear pumps use the rotation of gears to drive liquid transfer. Its characteristics of uniformly transporting liquids make it widely used in laser printers and other fields. Here is the role of gear pumps in different industrial printers:

·Photosensitive coating transportation: The gear pump is used in laser printers to transport photosensitive coating or toner to ensure that the coating on the photosensitive drum is uniform and stable to obtain high-quality printing results.

·Precise control: The rotation speed of the gear pump can be precisely controlled to adjust the thickness of the coating to meet different printing needs.

·High precision: Gear pumps often enable high-precision liquid delivery, ensuring consistent quality every time you print.

TOPSFLO MJ205 inkjet pump

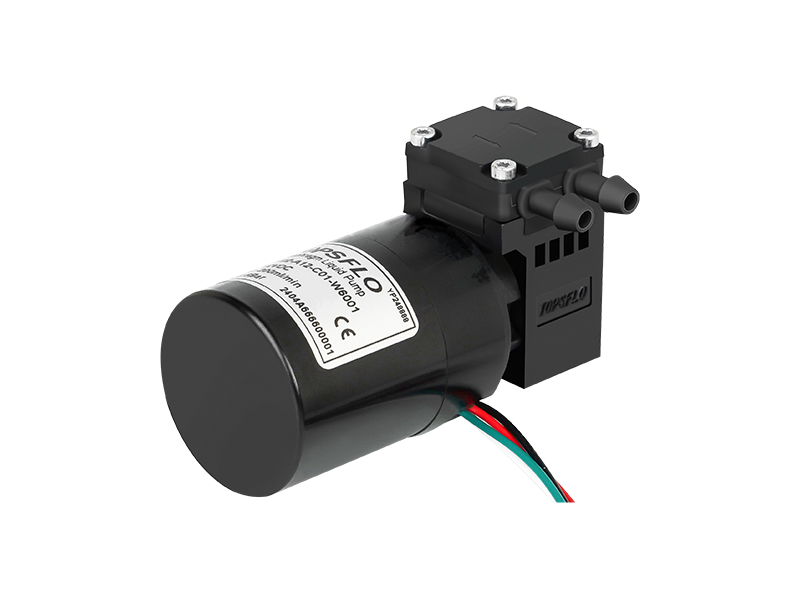

3. Centrifugal Pump

Centrifugal pumps promote liquid transfer through centrifugal force, and can also be used for cooling in industrial printers that require efficient cooling systems. They are mainly used in industrial printers, such as 3D printer,Laser cutting and engraving printer etc. The applications of centrifugal pumps in different types of industrial printers are as follows:

· Cooling system: The electronic components and print heads in industrial printers generate heat during work. Micro centrifugal pumps can be used to circulate cooling liquid and transfer heat to the radiator or cooling device to maintain a stable operating temperature of the printer.

·Stable supply: The centrifugal pump can provide a stable supply of ink or liquid, ensuring that large industrial printers will not have supply interruptions during long-term operation.

·High Flow: Due to its efficient liquid transfer capabilities, centrifugal pumps are suitable for printing tasks that require large volumes of liquid.

TOPSFLO TL-B10-A water cooling pump

To sum up, micro-pumps play an indispensable role in various types of industrial printers. Through different types of pumps, printers can achieve liquid transfer, control and cooling, thereby ensuring high-quality printing and long-term stability, providing industrial and efficient operation of commercial printers. In the future development, micro pump technology will continue to bring more innovation and progress to the industrial printer industry.

TOPSFLO specializes in the R&D and production of various types of industrial printer micro pumps. It has rich case experience and micro pump solutions, and provides customized services to meet different customer needs. Please contact a sales engineer for industrial printer pump application cases and pump information!

Email: info@topsflo.com