Meet Diverse Needs and Enhance End-user Experience I TOPSFLO DC Water Pump Intelligent Customized FG Signal

2024-01-03

As an advanced fluid transfer device, brushless DC centrifugal pumps are playing an increasingly important role in various industries. This kind of mini water pump not only has the advantages of high efficiency, low energy consumption and smooth operation, but also has the advantages of easy installation and use, long life and is deeply loved by users, becoming the preferred device in many fields. The FG signal of the brushless DC centrifugal pump is very important for monitoring, controlling and optimizing the operation of the pump, which can improve the stability, safety and efficiency of the system.

I.What is the FG Signal of a Brushless DC Centrifugal Pump?

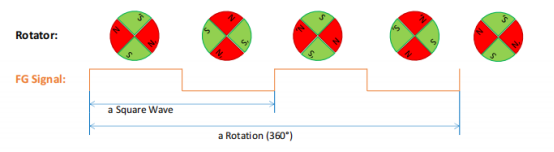

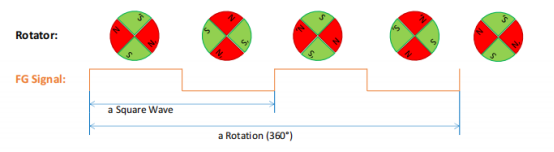

The FG signal of a brushless DC centrifugal pump usually refers to the "Frequency Generator" signal line, which usually work through a square wave signal. The frequency of this square wave signal is proportional to the speed of the mini water pump. When the motor speed increases, the frequency of the square wave signal will increase accordingly, and when the motor speed decreases, the frequency of the square wave signal will also decrease. Through the frequency change of this square wave signal, the control system can achieve precise control of the motor speed and control it as needed to ensure the stable operation of the mini water pump.

If the motor speed is lower than the set value, the control system can increase the output power of the motor by increasing the duty cycle of the speed regulation signal, thereby increasing the motor speed. On the contrary, if the motor speed is higher than the set value, the control system can reduce the output power of the motor by reducing the duty cycle of the speed regulation signal, thereby reducing the motor speed.

How is the square wave generated? The FG signal is actually the communication signal of the brushless DC motor. When a communication event occurs, the FG output will toggle. The rotor used in the TOPSFLO mini water pump has 4 poles, which means that 4 communication events will occur during one rotation of the rotator, and the FG will flip twice to produce a square wave.

II.Wiring Method of the FG Signal Line

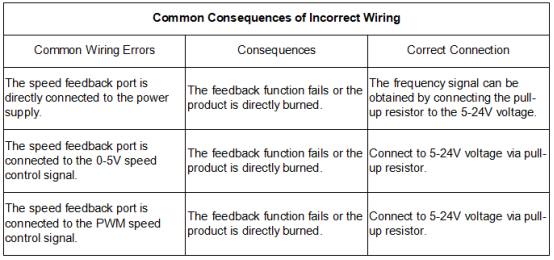

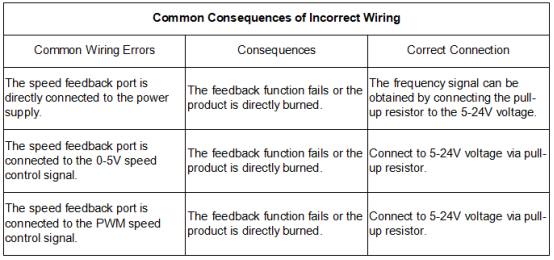

The wiring sequence of the customized 5V/PWM/FG signal line of TOPSFLO DC brushless water pump is generally: red line positive, black line negative, blue line 5V or PWM speed regulation, yellow line FG signal. When the red, black and yellow wires are connected, the water pump works normally; when the yellow wire is not connected, the mini water pump works, but there is no signal display; when the input current is >50mA, there is a risk of damage to the FG signal circuit of the pump. When measuring speed, a pull-up resistor must be connected. The pull-up resistor is recommended to be between 1K and 10K. It is adjusted according to the pull-up voltage. The greater the voltage, the greater the resistor selected.

FG Wiring Precautions

III. What kind of applications need to customize the FG signal lines?

The reasons for customizing FG signal for brushless DC centrifugal pumps involve many aspects such as control system requirements, accuracy, integration, and performance optimization. By customizing FG signal lines, customers' specific needs can be met to ensure that the water pump can achieve the best performance and functionality in its applications. The following are common applications that require customized FG signal lines:

1.Equipment control system requirements: The customer's control system requires specific types or specifications of signal inputs to ensure optimal performance. For control systems that require specific frequency ranges or signal types, customizing FG signal lines to meet these requirements is necessary.

2.Precision and accuracy requirements: Customer applications require higher measurement precision and accuracy, such as the medical industry, drinking industry, cooling industry, precision instruments, etc. By customizing the FG signal line, the speed of the water pump can be precisely controlled. For example, the speed regulation function needs to be implemented or the pump needs to run at a specific speed under specific conditions. At this time, the FG signal line can provide the operating status and speed information of the water pump to facilitate customers to accurately control and adjust the water pump.

3.Real-time monitoring requirements: The operating status of the water pump needs to be monitored in real time. For example, it is necessary to know the flow rate of the water pump or whether it has stopped due to failure. At this time, customized FG signal lines can collect and monitor these data, helping customers promptly detect abnormal pump operation and take corresponding measures.

4.Integration and compatibility requirements: Customized circuits or wiring schemes are required for customer system integration to meet the overall system design and requirements. In this case, customized FG signal lines can better meet the needs of system integration, providing a more flexible and reliable system solution.

IV.Advantages of TOPSFLO's customized FG signal lines

TOPSFLO is one of the earliest manufacturers in China to focus on the R&D and manufacturing of micro pumps. It is a powerful enterprise that only produces high-end products and exports 90% of them to the European and American markets. It has long-term and stable cooperation with many world-renowned brands in Europe and the United States, and its business has been growing steadily every year. At present, the full series of TOPSFLO TL brushless DC centrifugal pumps can realize intelligent customization of FG signal lines. Our advantages are mainly reflected in the following:

1.R&D strength: TOPSFLO has independent electronic engineers, structural engineers and motor engineers to provide you with support and R&D. Each has their own practical R&D capabilities and can be flexibly customized according to customer requirements, ensuring that you can always receive a solution immediately. You can rest assured of our high-quality and professional service in the long run.

2.Successful cases: TOPSFLO cooperates with many leading international companies and provides OEM supporting services, such as Tesla, Whirlpool, Bosch, KTM, KOHLER, etc. Therefore, we have extensive experience in pump applications and OEM services in different industries, such as medical, solar pv, automotive, industrial cooling, home appliances, charging piles, hot beverage machines, etc.

3.Company strength: With nearly 18 years of experience, TOPSFLO is the leading comprehensive solution manufacturer in China specializing in the production of various DC micro pumps. We attach great importance to product quality and corporate integrity, which is why we have a strong R&D team to realize customers' customized needs throughout the process.

TOPSFLO can not only customize the speed regulation function of 5V, PWM and FG signal lines, but also realize the customization of pump size, structure, materials, etc. Any OEM project you can imagine and request for customization, TOPSFLO will try its best to meet your requirements. If you have any further questions, please feel free to let us know. We value your valuable suggestions and look forward to cooperating with you.