Visit TOPSFLO with KTM and discover the secret of the pump's quality leadership

2024-06-18

KTM, with its excellent quality, extraordinary performance and unique design,has become the global leader in the field of off-road motorcycles, leading the way in the world of off-road motorcycles and winning wide acclaim from riding enthusiasts all over the world. KTM's strict quality requirements are the cornerstone of its success, and as a pump manufacturer that has been cooperating with KTM for 12 years, Topsflo Pumps takes this as a driving force for progress.

.png)

The values that KTM shares and the dedication to pump quality were the key reasons why KTM chose Topsflo Pumps.

Recently, we have welcomed KTM's fourth factory audit, let's follow KTM's footsteps, visit Topsflo and reveal the secret of leading quality.

Step 1: R&D Laboratory Center

Topsflo invests 10% of its annual turnover in the construction of R&D laboratories. So far, we have set up four major industry frontier laboratories in line with the CNAS national laboratory standards, including - precision and physics laboratory, electronic motor performance laboratory, environment and durability laboratory, noise test and analysis room. We have built a professional pump R&D team and introduced talented engineers with more than 20 years of industry experience. In order to the accuracy of product precision and testing, it is imported dozens of advanced imported testing equipment, which provides strong support for product development and testing.

.png)

At present, TOPSFLO has customized professional dc water pump solutions for more than a hundred well-known enterprises around the world, including many of the world's top 500 companies.

Step 2: Anti-static dust-free production workshop

We firmly believe that good quality comes from a good working environment, Topsflo production workshop follows the American ANSl standard to build ESD static management system, to ensure that the products are free from potential static interference, advanced and perfect full set of anti-static control so that customers frequently nod.

Topsflo’s production site implements strict 6s management, the production area is bright and clean. Material storage is clear, designated materials are placed in designated locations, and employees return the materials to their original places after use.6S management can strongly reduce the waste of personnel, equipment, place, time and other aspects, improve employee productivity, shorten the production cycle, and reduce production costs.

At the same time, Topsflo builds intelligent production lines and introduces more than one hundred advanced production equipment that are in line with the international standards, so as to realize the double improvement of production efficiency and product quality.

Step 3: Fully automated injection molding workshop

Based on customer demand and internal injection molding standardization needs, combined with on-site quality management requirements, Topsflo injection molding workshop strictly implement ls09001, promote injection molding quality management related processes programmed to ensure product quality, to meet customer requirements, to implement the spirit of lSO, and through a number of important customers factory inspection audit.

Topsflo injection molding workshop introduced several sets of imported injection molding equipment, supporting robots and conveyor belts, has realized the automated intelligent production of plastic parts, greatly improving the overall delivery speed of the product production, plastic parts and the overall quality of the pump has been further improved.

Step 4: Intelligent control of the warehouse

Topsflo intelligent warehouse is equipped with PDA scanning code in and out of the warehouse, and intelligent warehousing WS system and the company's ERP management system data interoperability, warehouse intelligent equipment system import, promote the warehouse efficiency, electronic tags to replace the traditional handwritten billing card, information management of the warehouse and the binding of materials, through the two-dimensional code, barcode technology and wireless terminal technology to achieve the auxiliary materials spare parts visualization, digital management lt also realizes the visualization and digital management of auxiliary spare parts through two dimensional code, barcode technology and wireless terminal technology, first-in-first-out, easy traceability and other functions.

Step 5: Three phases of the new plant

In addition, we also took our customers to visit the new factory of Topsflo Phase lll. Our new factory building is scheduled to be put into production by the end of the year, and is expected to introduce 5 automated production lines, more than 100 sets of high-end equipment, and the degree of automation in the production hall is expected to be more than 80%. This will create a sustainable micro pump manufacturing plant with high quality, short lead time and enhanced competitiveness.

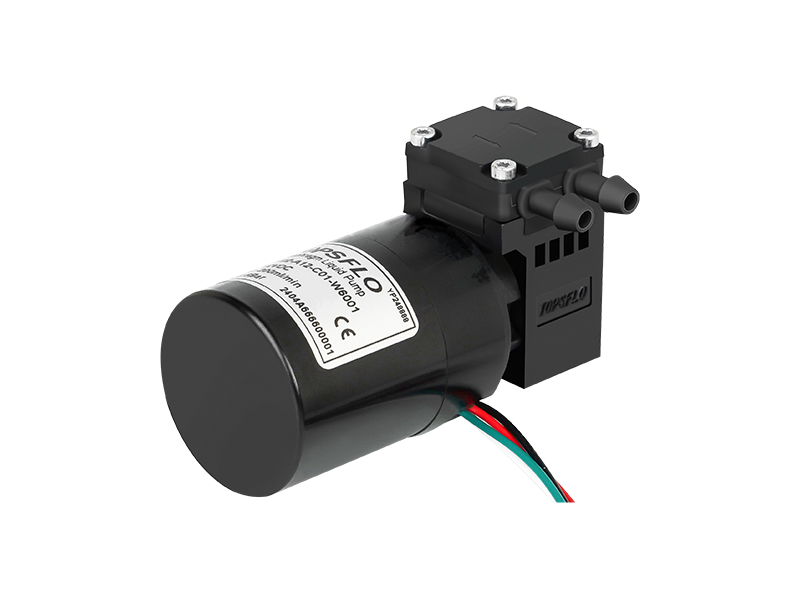

After visiting the company, the customer also shared KTM's corporate philosophy and pursuit of product quality with Topsflo, and very much recognized Topsflo’s pursuit of excellence in the field of brushless centrifugal pumps.and the customer believed that the success of a brand is its strict requirements for quality and its attitude of striving for excellence. In terms of quality assurance,Topsflo Pumps strictly follows the lSO 900l and TÜV16949 dual quality management system standards certified by Rhineland. From the selection of raw materials to research and development, production, quality control and other aspects, we are strictly controlled. 80% of TOPSFLO pumps are made of imported raw materials, all the materials are not recycled, and the electronic components are all original parts of international famous brands. We also have 6 100% inspection processes that are stricter than the industry and national standards to ensure that each finished pump can be delivered to customers in a "zero defect" state.

It is through rigorous quality assurance measures and the spirit of continuous innovation that Topsflo Pumps is able to work hand in hand with the world's top brands such as KTM to create an outstanding product experience. in the future, Topsflo will continue to uphold its commitment to quality and pursuit of innovation, and provide even better products and services to customers around the world.

Dear Amy and Penny,

Thank you so much for the warm welcome and wonderful day at Topsflo. It was indeed like meet up of old friends. Your team is so vibrant and we felt such a positive vibe from you and Thank You all so much for your whole hearted effort to keep the relationship with KTM with positive outlook for the points we have discussed.It is indeed my pleasure to work with your team where we have a positive outlook towards a future together.

We are looking forward to your visit to KTM.

.png)

.png)