It took two and a half years! Why choose TOPSFLO for the world-famous home energy storage project?

2023-03-01

Lead: TOPSFLO provides the key core component of the liquid cooling system - water pump for the home energy storage project of the world's well-known electric vehicles and energy company. During the communication phase, TOPSFLO learned that customers have important requirements for the sealing of water pumps, because leakage and electronic failure will bring fatal risks to the entire system. The customer spent 2.5 years on repeated tests and verifications, and at the same time compared and tested many pump suppliers in Korea, Japan, China, etc., and finally chose TOPSFLO liquid cooling pumps. TOPSFLO has been optimized from four aspects: parameters, structural sealing design, low temperature resistance verification,and intelligent design. The optimized product meets the needs of customers and achieves the best matching degree.

On December 4, 2012, TOPSFLO's sales engineer received an email from Peter, a senior mechanical engineer in the United States, and learned that he was looking for a suitable water pump for the development of the company's new home energy storage product.

This is the world's leading electric vehicle and energy company who is changing the way the world powers and accelerating the world's transition to sustainable energy through electric vehicles, solar products and integrated renewable energy solutions for homes and businesses .

Communication stage: water pump tightness is the primary consideration

As the wind vane of global electric vehicle and energy companies, the company's home energy storage product is extremely pioneering in the industry. After receiving the email, we responded immediately to gain an in-depth understanding of the characteristics of home energy storage in order to further communicate the needs.

Home energy storage can store solar energy, or charge during the low peak period of grid power consumption (low price), release the stored power to power homes during power outages or peak power consumption periods, and can also charge electric vehicles. It is equivalent to installing a giant power bank in the house, which can save users money, reduce carbon emissions, and calmly deal with power outages.

However, the product itself also has a big challenge - when the device is charging and discharging, the battery pack and inverter will generate a lot of heat, which needs to be regulated temperature by the cooling system. Because the power of home energy storage is generally less than 30KW, natural cooling or air cooling is generally used in the market, but the disadvantage is that the overall product design will be larger and the cooling effect may be uneven.

As the world's leading high-end brand, the company chose the liquid cooling method with the most technical difficulty but the best cooling effect. The technical difficulty of the liquid cooling method lies in sealing and intelligent regulation, and pipelines and water pumps are the key core components of the cooling system. Water pumps leakage and electronic failures pose fatal risks to the entire system.

Therefore, the tightness of the water pump is one of important aspects that customers focus on.

Testing phase: up to 2.5 years of verification and comparison

Home energy storage was a world-leading design concept at that time, and there was no similar application in the market to learn from. Therefore, in terms of water pump selection, the customer spent 2.5 years on repeated tests and verifications, and at the same time compared and tested many other water pump suppliers from South Korea, Japan, and China,etc., and finally TOPSFLO stood out from them.

Throughout the entire process, according to customer needs, we have optimized the following aspects:

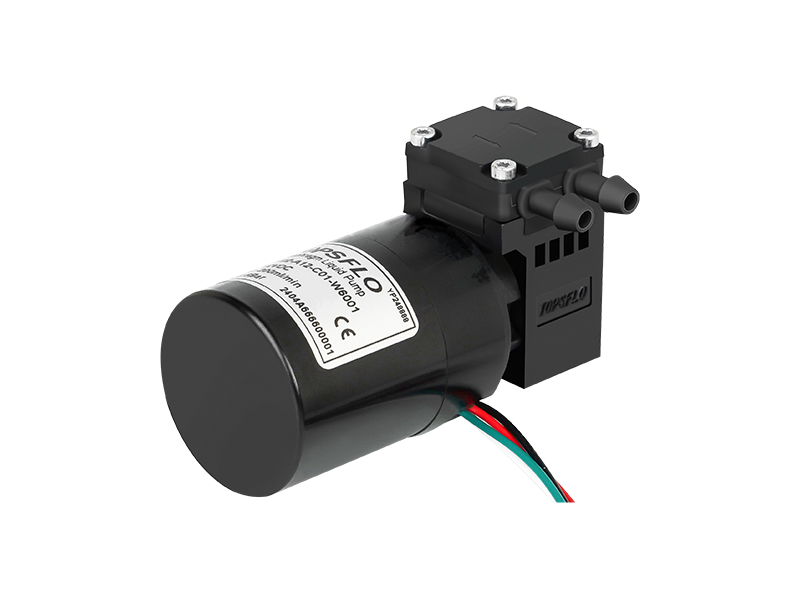

1. Parameters: From the smallest TL-A series of TOPSFLO brushless DC micro pumps to the larger parameter TL-C series, after many times of sample testing, and according to each different test results, the electronic scheme of the pump motor is adjusted. Finally, TL-B10 home energy storage liquid cooling pump (parameters: voltage 12V, flow rate 10L/min, head 6m) reached the best matching degree.

2. Structural sealing design: The advantage of liquid cooling is that it has a good cooling effect, saves space, and has low energy consumption, which can better ensure battery consistency. However, possible leakage has always been a technical problem that is generally feared in the industry. In order to achieve better sealing, we designed a multi-barbs water inlet and outlet connection method for customers, and under the support of high-precision molds, the surface finish of the water inlet and outlet is high, and the seal with the liquid cooling pipe is tighter.

3. Low temperature resistance verification: The customer's products are mainly sold to Europe and the United States, and are generally installed outdoors. There are many extremely cold weather, and the water pump must meet the automotive grade low temperature resistance of -40°C. We use international well-known brand raw material suppliers for customers, such as Xyron plastic materials, Atmel chips, etc., and the temperature resistance and reliability have reached the industry's leading level. Before mass production, the water pump has passed multiple verifications such as low temperature operation at -40°C, storage at -40°C, low temperature start at -40°C, high and low temperature shock test at -40°C & 120°C, and the pump was not leak under extreme environments.

4. Intelligent design: The water pump is specially customized with 5V intelligent speed regulation and signal feedback function, which can perform signal feedback and intelligent speed regulation in real time according to the battery temperature demand, so as to maintain the stable operation of the system, prolong the life and save energy.

For as long as 2.5 years, TOPSFLO has won the favor of customers by virtue of the high quality of water pumps and his professionalism in the micro pump industry, and has become their core component supplier. On June 9, 2015, the first generation of products officially entered mass production, with the first order of 5,000 units.

Cooperation stage: At least 3 times a year to strictly inspect the factory

From the first audit of TOPSFLO factory in April 2015 to the stable mass production of the second generation of products in 2018, the customer quality team conducts audits at least 3 times a year, which shows the strict quality control of suppliers and pumps.

1. Electronic control

From the PCBA layout design, the selection of each electronic component and supplier qualification, to the SMT process, welding fixtures and pad void rate, soldering flux, and then to the cleanliness of the workshop and ESD anti-static control, etc., all are controlled and one-by-one reviewed by the customer SQE team, continuously proposes improvement directions and requires optimization.

2. Quality

Although this cooling water pump is not used in automobiles, the customer has been auditing strictly in accordance with the IATF 16949 (TS 16949 at the time) quality management system.

In order to fully meet the high quality requirements of customers, the TOPSFLO factory adopts the most authoritative German TÜV IATF 16949 quality system audit, and has become one of the few micro pump manufacturers in China that has obtained the German TÜV ISO9001 and IATF 16949 dual certification.

In addition, from the procurement of raw materials to each production process, each testing link and the whole process of testing data, the traceability control of small batches has been realized, and the details are down to 500 units per small batch, and the specific time and operators are very clear.

3. Testing equipment and research and development capabilities

Automated production equipment and high-precision testing equipment are the guarantee of quality consistency and production efficiency.

At that time, in the micro-pump industry, most of the operations were manual or with low-precision equipment, and most of the equipment on the market was not universal for water pumps.

Therefore, the TOPSFLO R&D team independently develops personalized testing equipment and introduces foreign customized equipment, such as air tightness detectors, automatic glue filling machines, comprehensive performance test benches, etc. From the initial manual or semi-automatic to the current national laboratory standards, it has far exceeded customer expectations.

TOPSFLO achieves more efficient production capacity while meeting customers' high-quality needs.

It is an honor to cooperate with high-quality customers, and TOPSFLO is lucky to achieve its own iterative growth with the help of customers.

Every technical problem, every high-standard testing requirement, every piece of equipment's accuracy requirements, and every non-conformity item raised in the audit are all supervision and improvement for us, and inspire us to continuously achieve breakthroughs.

Good quality of products, continuous innovation of technology, high satisfaction of customers, TOPSFLO’s pursuit on them will never end!