High-power liquid-cooled charging pile water pump of TOPSFLO helps electric vehicles achieve safe and fast charging

2022-11-21

As the "gas station" for new energy vehicles, the charging time of new energy vehicle charging piles is much longer than that of traditional vehicles. In addition, the sales volume continues to skyrocket, resulting in anxiety about battery life, and the supply is in short during holidays. The hot search entry " A man driving Tesla back home stuck in traffic until no electricity to call a tow truck” during the recent National Holiday has aroused heated discussions among netizens.

Compared with the slow charging of "slow water flow", the convenient and efficient fast charging pile is obviously more in line with the appetite of consumers. In order to meet the "fast charging" demand of the charging pile of new energy vehicles, the output power needs to continue to increase, and the heat flow density of the charging system will increase significantly. Its system security is facing major challenges.

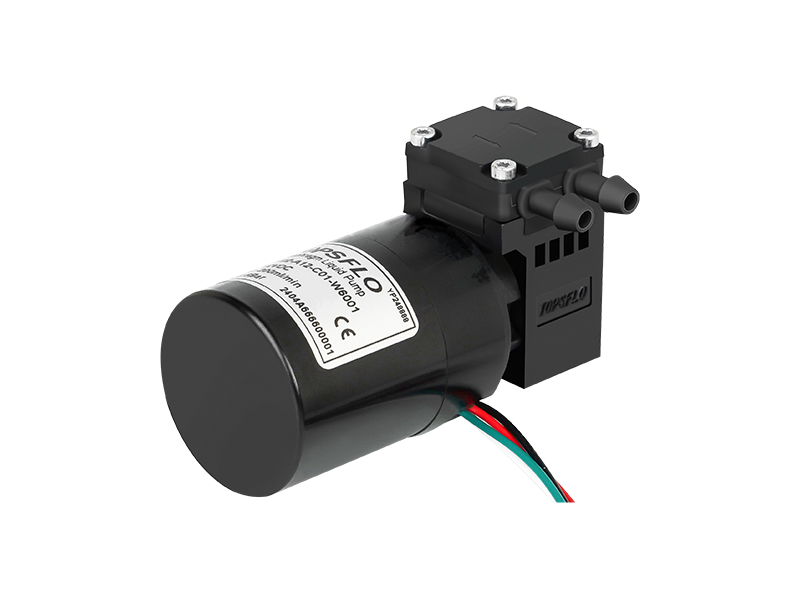

To solve this problem, the choice of liquid cooling circulating water pump is indispensable. When selecting the water pump for new energy vehicle charging pile manufacturers, they should see whether it can maintain excellent reliability, long life, silence, water and dust resistance etc. in the high and low temperature environment of - 45~80 ℃, and if it can achieve multiple protection, intelligent control and other functions.

The application of liquid coolant pump in the charging pile of new energy vehicles mainly includes two aspects:

1. Liquid cooling module

The liquid cooling circulation system of DC charging pile consists of multiple liquid cooling modules, and the circulating pump and diverting valve are used to evenly distribute the coolant to multiple liquid cooling modules. The shape of the pipeline inside the liquid cooling module is determined according to the distribution position of the heating device in the charging pile, and the cooling liquid is used to cool the heating device in the cold plate channel.

2. Liquid-cooled charging cable

Liquid cooled cable is a special cable used for high current heating equipment. A special circulation channel is provided between the cable and the charging gun, Coolant is added into the channel, and the power pump drives the liquid circulation to bring out the heat, playing a role in heat dissipation. In March 2019, Tesla V3 overcharge pile appeared in the world. The diameter of the liquid cooling charging cable used is about 44% smaller than that of the V2 overcharge pile, only 23.87mm. The maximum peak power of this overcharge pile can reach 250kW.

The EV fast charging coolant pump can fully meet the heat dissipation requirements of high-power charging pile and reduce the heat damage caused by high-power charging to the charging gun, charging cable and charging pile.

As early as many years ago, TOPSFLO has carried out in-depth research on the cooling application of charging pile. The liquid cooling water pump of TOPSFLO has many advantages that ordinary water pumps in the market cannot match, such as small size, good cooling effect, high and low temperature resistance, long life, maintenance free, intelligent control etc. It can also be customized according to customer needs, including EMC electromagnetic compatibility solutions etc.

Each TOPSFLO coolant pump has passed strict high and low temperature fast switching test of the whole machine, meeting the requirements of different working conditions of the super charging pile, and uses international famous brand electronic components, which has lower heat generation and high reliability. TOPSFLO brushless DC charging pile pump has the functions of 5V/PWM speed regulation and FG speed signal feedback, which can realize automatic intelligent detection, support failure alarm, real-time data feedback, etc., and protect the high-efficient liquid cooling overcharge pile.

As an indispensable part of the new energy vehicle industry chain, the charging pile has been incorporated into the new infrastructure construction with the strong support of national policies and driven by market demand, and with a very broad development prospect. With nearly 20 years of industry experience, TOPSFLO focuses on the research and development and manufacturing of brushless DC water pumps. It will take technology as the guide, adapt to the general trend of electrification and intelligence in the global automobile industry, and help the charging pile open new opportunities for development.