Low voltage DC pump or high voltage AC pump which is more suitable for us to use?

2022-03-22

Before starting this question, let us understand what is water pump first? Waterwheels, tackles and other water-carrying tools are the prototypes of water pump in ancient times. With the development of production and people's understanding and mastery of the laws of nature, these ancient water-carrying tools have gradually developed into today's water pump.

Water pump is a mechanical device used to lift liquid, transport liquid or increase pressure on liquid. Now the water pump, as a kind of general equipment, has been widely used in various fields of daily life. For example, in agricultural production, pump are mainly used for irrigation and drainage. Our country's agricultural area is vast, and a large number of pumps are needed in agriculture every year. Our country is also a big manufacturing country, and pump are also needed to transport all kinds of liquids in the food industry. It can be said that where the liquid needs to be transported, the pump will be used! The importance of the water pump to the water delivery equipment is like the heart to the human body. It is the core part of the water delivery process. Pump is so important and there are so many types, we equip the equipment with a suitable pump so that the equipment can be used to the best effect.

We simply start from the voltage range, and generally divide the pump into low voltage DC pump and high voltage AC pump, so which one is more suitable for us? This article will start a chat with everyone about the structure, characteristics and scope of application of the two types of pumps:

High voltage AC water pump generally refer to AC 220V, 380V and other AC power supplies (industrial use). The working principle of the high voltage AC water pump is mainly to use the periodic change of the inner volume of the working pump cavity to transport the liquid.

Maybe everyone is unfamiliar with high voltage water pump, but in hot summer, we can all see it in sprinklers on the street, pumping machinery, and fire sprinkler device on fire truck. Mainly used in agro-industrial fields such as liquid spraying, spraying and irrigation.

Taking the reciprocating type as an example, the volume in the pump cavity is changed by the reciprocating piston or plunger, and the process of inhaling and pressing out the liquid is completed to achieve the purpose of conveying the liquid. The structure is shown in the figure:

The characteristics of the high voltage AC water pump are as follows:

1.High voltage current. When connecting to 220V, 380V power supply, the insulation requirements are extremely high, and special attention should be paid to the problem of wire damage. Once the wire is damaged, it is very likely that electric shock, leakage and other safety accidents will occur.

2.Low lifespan, not resistant to high temperature. The high voltage AC pump motor generally uses a copper-clad aluminum wire core, and the stator coil winding wire diameter in the motor is relatively thin and the number of winding turns is large. When the motor is working, the internal temperature of the product is generally as high as 120 degrees or more. And because most of the high voltage AC pumps use electricity in urban areas, the voltage is relatively high. To make water pump with the same power density, it requires much more steel and copper than Low voltage DC brushless pump, and the efficiency is not high, and the product has poor heat dissipation, so it is not suitable for use in high temperature environment.

3.Large size. Due to its own structural design and application field, the size of the high voltage AC pump will be larger than that of the low voltage DC water pump.

4.High noise. The high voltage AC pump currently uses the motor technology of the early years, and it is related to its own steel and copper. As a result, the noise of high voltage AC pump on the market is generally high, the noise gets louder as the user spends longer.

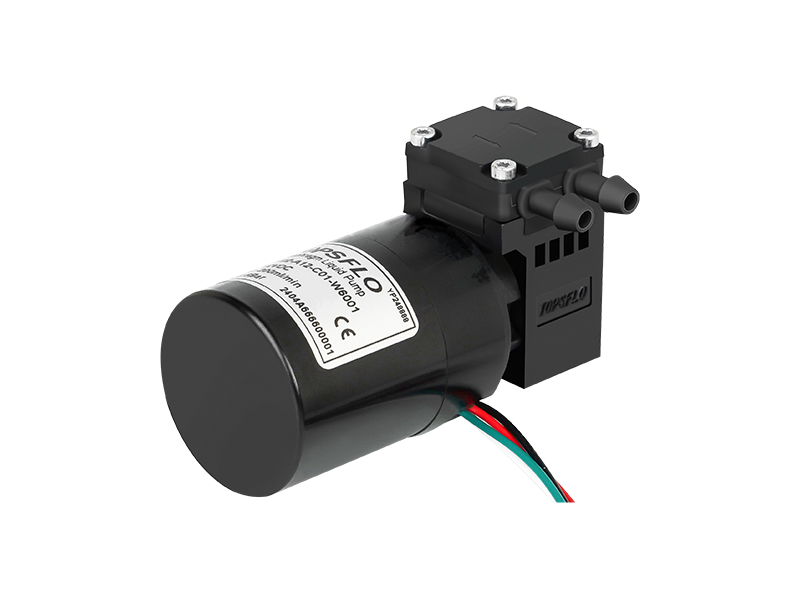

Low voltage DC water pump generally refer to DC 12V, 24V, 36V and other DC power supplies (commercial & households). Low voltage DC water pump involved in this article mainly refers to the brushless DC pump. The brushless DC pump is driven by the brushless DC motor through the magnetic force of electronic commutation, without the use of carbon brushes, and is driven by the brushless carbon brush motor. There is no wear of the commutator and carbon brush, which reduced the noise and prolongs the service life, performance parameters, reliability and consistency have all been improved to a certain extent. The structure is shown in the figure:

.jpg)

Compared with high-voltage AC pumps, brushless DC pumps have the following obvious advantages:

1.Safer. We all know that the safety voltage of the human body is 36V, and the dc brushless water pump uses a low voltage of 12V/24V. Even if the cable is damaged, there is no need to worry about the occurrence of safety accidents caused by electric shock. Moreover, in the case of a power failure, the pump can also be powered by the corresponding battery, which is more convenient.

2.Long lifespan. Brushless motor, no carbon brush loss; especially the brushless motor used by Changsha TOPSFLO, which uses imported precision ceramic shafts and graphite shaft sleeves, never wears out.

3.Lower power consumption. The BLDC motor can accurately feedback the target number of revolutions, torque, etc. Heat generation and power consumption of the motor can be suppressed by precise control.

4.Intelligent control. Built-in intelligent chip, can adjust the flow; realize signal feedback, failure mode feedback, and has multiple intelligent protection functions.

5.Small size, higher efficiency. The brushless DC mini pump has a built-in variable frequency brushless DC motor, no carbon brush commutation, no mechanical friction heating, low power, and small temperature rise. It solves the problems of low energy efficiency, large size and high noise of the high voltage AC pump. Generally speaking, the efficiency of the brushless pump of the same volume can reach 2~3 times that of the AC pump, and the volume is 1/3~1/2 of the AC pump.

6.High temperature resistance liquid. The temperature of the liquid generally used in the brushless DC pump on the market is not higher than 70 degrees. At present, Changsha TOPSFLO Pump Co., Ltd. can customize brushless DC centrifugal pump with high temperature resistance up to 125 degrees.

7.100% waterproof, never leak. The rotor is integrally formed, the stator and the rotor are completely isolated, and the static seal replaces the traditional shaft (dynamic) seal. The liquid is completely isolated from the motor and never leak. And it can be fully submersible and 100% waterproof, effectively improving the service life and performance of the pump.

8.Low noise. Under the same performance, the brushless DC centrifugal pump of Changsha TOPSFLO will be 15-20dB lower than the high voltage AC water pump with the same performance.

Because the brushless DC pump has many advantages, such as reliable operation, convenient maintenance, high efficiency and intelligent control. Its application range has gradually replaced the application field of high voltage AC water pump, and has spread to all fields of the national economy and people's daily life. For example, our daily water dispenser, water heater, smart toilet, and car; as well as commercial appliances such as medical equipment, beauty equipment, and irrigation equipment.

Through the above analysis, the editor believes that with the continuous improvement of the level of social science technology and the quality of life, brushless DC pump are more suitable for our use, and gradually become the mainstream, replacing most of the fields that require high voltage AC pump. However, each type of pump has its own characteristics, and no one type of pump can be suitable for application requirements in all fields, only the ones that fit the development needs are the best.

Well, that's all we're going to talk to everyone about today. If you have different views and suggestions, you can leave us a message, and look forward to communicating with you!

.jpg)