Analysis on the Principle, Structure and Application of Pump of Biochemistry Analyzer

2022-12-12

Biochemical diagnosis is the earliest automated detection method, and it is also one of the most commonly used in vitro diagnostic methods. Biochemical diagnosis is often used for basic examination items such as liver function, kidney function, blood sugar and lipid. It is used in combination with biochemical diagnostic reagents and biochemistry analyzer to determine whether the human body is in a healthy state by measuring the content or activity of specific biochemical substances.

The currently commonly used automatic biochemical analyzer is a biochemical analysis instrument that automates the steps of sampling, adding reagents, mixing, heat preservation reaction, detection, result calculation and display, and cleaning in the analysis process. Due to the high degree of automation and the functions of calibration and automatic correction, the subjective error and system error are relatively small and easy to use.

•Working Principle

The colored liquid in the cuvette is irradiated by multiple vertical monochromatic beams;

Through the absorption of light energy by the measured sample, the light signal is converted into a corresponding electrical signal by the photoelectric converter;

The signal is amplified, rectified, and converted into a digital signal, which is sent to the computer;

Computer-controlled drive electric drive filter wheel and sample tray;

Then the measurement data is processed, calculated, analyzed and saved according to the working mode selected by the user;

The printer prints the corresponding results simultaneously;

After measuring each set of samples, the cuvette was cleaned.

Basic Structure

Structurally, the automatic biochemistry analyzer includes sampling system, reagent system, reaction system, cleaning system, pipeline system, colorimetric system, computer system, etc.

1. Sampling system: it is the key device for adding quantitative samples (usually microscale) and reagents to designated cuvettes for reaction. The dispensing and sampling device is mainly composed of syringe, stepping motor or transmission pump, sampling arm and sample probe, etc.

2. Reagent system: it generally consists of a reagent storage device and a dispensing&liquid filling device. The dispensing&liquid filling device is similar to the sampling system. The reagent probe can often pre-warm the reagent. The initial amount of the reagent 2 (R2) probe in the dual reagent system should be relatively low in order to match reagents with different R1/R2 ratios.

Reaction system: reaction cuvettes are mostly in the form of a turntable. During the reaction measurement process, the sample loading arm, the liquid loading arm, the stirring rod, the optical path and the cleaning device are rotated according to a fixed program. The biochemistry analyzer uses a temperature control device to keep the incubation temperature regulated and constant.

Cleaning system: Probes and stirring rods are automatically flushed by means of torrent. The cleaning device generally consists of a suction needle, a discharge needle and a wiping brush. Generally speaking, after aspirating the reaction solution, the instrument is first rinsed with alkaline solution, then with acidic solution, and finally with deionized water for three times.

Computer system: The computer is the brain of the automatic biochemistry analyzer. The injection and identification of specimens and reagents, barcode identification, constant temperature control, flushing control, result printing, quality control monitoring, and alarms for various instrument failures are all performed by the control of computer.

Application of Biochemistry Analyzer Pumps

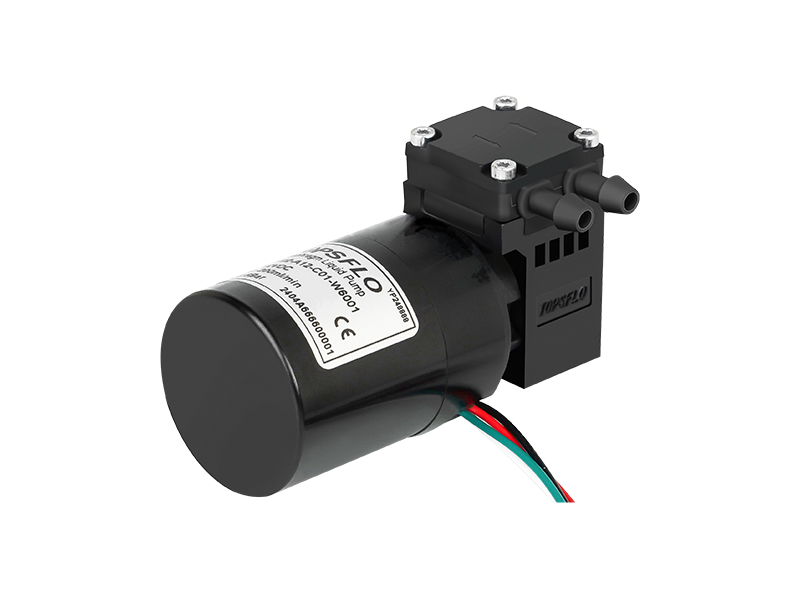

In a biochemistry analyzer, micro medical pump is a common fluid-driven component that has multiple functions such as sample transmission, reagent cooling, deionized water circulation, temperature control system cooling, waste liquid removal, and probe cleaning.

As a precision medical equipment, biochemistry analyzer has very strict requirements on the performance of Direct Drive pumps, and also have high requirements on the cleanliness of equipment pipelines, it must without impurities and particles being precipitated, and without any pollution. In addition, biochemistry analyzers are generally used in hospitals and other places, which have very high requirements for noise and vibration. Based on safety considerations, the operating voltage must be 12V/24V safe voltage.

The miniature brushless Direct Drive centrifugal pump produced by Topsflo fully meets the pump requirements for biochemistry analyzers. It has long life, low temperature rise, low noise and other performance advantages, and has passed the "particle test" for several months by the world's leading medical technology company, 24 hours a day for 30 consecutive days. The deionized water was continuously pumped, and no impurities were detected under a 200-fold microscope, and no pollution was caused, which was highly praised by customers.

Since its establishment, Topsflo has always strictly demanded itself with the highest standards in the world. The standards set in R&D, production, and quality control are higher than those of domestic counterparts. Topsflo keeps pace with Bosch, Iwaki, and Nidec internationally, and provides competitive high-quality products for multiple industries. For more information on pump solutions for biochemistry analyzers, please contact Topsflo pre-sales engineers!