Topsflo's Liquid Cooling Energy Storage Electronic Water Pump Empowers Home Energy Storage Safety

2022-10-31

The liquid cooling energy storage industry has been closely watched recently, and some institutions predict that the market space of liquid cooling energy storage will explode by 25 times in four years. What is liquid cooling energy storage? What are the components? What are the characteristics? Topsflo engineers will explain it to you in detail.

Thermal runaway accidents of energy storage occur frequently

To understand liquid cooling energy storage, it is necessary to start with energy storage temperature control technology. Liquid cooling energy storage is a type of energy storage temperature control technology.

Energy storage temperature control is the key to preventing the capacity decay, life shortening, and thermal runaway of the energy storage system. The energy storage system has a large number of batteries, large battery capacity and power, and requires effective battery thermal management. Otherwise, it may lead to a decline in battery charge and discharge performance, capacity, and life, or even lead to thermal runaway, resulting in safety accidents.

From 2011 to 2021, a total of 32 energy storage power station fires and explosions occurred around the world. From January to May 2022, more than 10 energy storage fire accidents have occurred around the world. Thermal runaway of batteries has become the main cause of fire accidents. Frequent fire incidents highlight that energy storage temperature control has become an essential and important component to ensure the safe operation of energy storage power plants.

Liquid cooling is the long-term trend of energy storage temperature control

Energy storage temperature control mainly includes air cooling, liquid cooling, heat pipe cooling, phase change cooling and other technologies. Among them, air cooling is to take away the heat in the energy storage system in the form of air convection, and liquid cooling is to take away heat by using liquids such as water and ethylene glycol as the heat transfer medium. Phase change cooling and heat-pipe cooling are currently less practical and are still in the laboratory stage.

The basic components of the liquid cooling system include: liquid cooling plate, liquid cooling unit (heater optional), liquid cooling pipeline (including temperature sensor, valve), high and low voltage wiring harness, coolant, coolant water pump, etc.

On the whole, liquid cooling has higher heat dissipation efficiency and heat dissipation speed, and can better control the temperature difference between batteries. Therefore, its energy consumption is lower and the system life is longer, thereby helping the energy storage system to reduce the cost of the whole life cycle. Although the current domestic energy storage thermal management is still dominated by air cooling, under the trend of high-capacity and high-rate energy storage, liquid cooling solutions are more suitable for high-temperature or large-capacity scenarios. In the future, as the demand for energy storage stations with larger battery capacity and higher system power density, such as new energy power stations and off-grid energy storage, starts, it will promote the industry to adopt more liquid cooling solutions.

5 essential features of high-quality energy storage electronic pumps

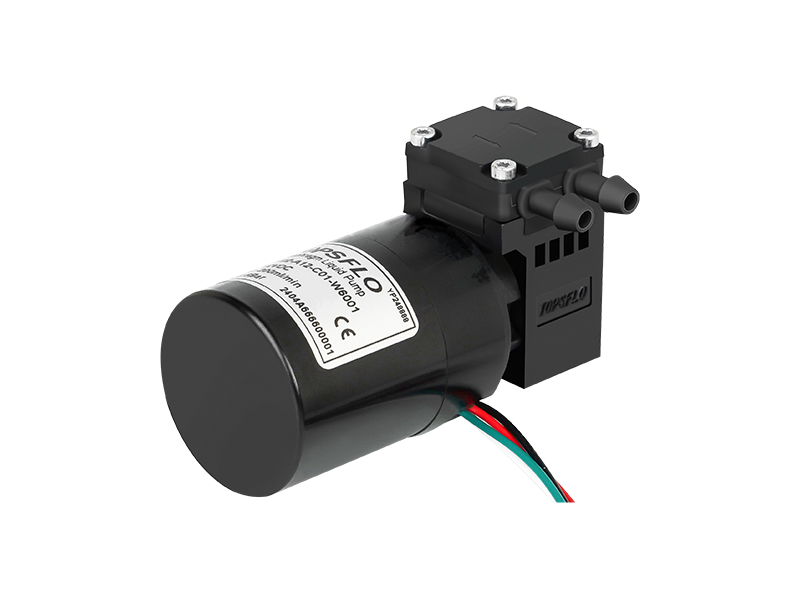

The energy storage liquid heat dissipation solution needs to drive the liquid in the pipeline to circulate through the electronic water pump, take away the performance of the excess heat of the battery system, and achieve the best working temperature conditions of the battery pack. Therefore, the electronic water pump, as the core component of liquid cooling, is very important.

So, what are the characteristics of high-quality energy storage electronic water pumps?

First, longer life. Long-life pumps help reduce operating costs and increase the life of the energy storage system. Topsflo pumps use high-efficiency brushless DC motors, imported chips, and high-precision silent rotors, with a lifespan of 30,000 hours, which is much higher than that of ordinary pumps on the market.

Second, the temperature rise is lower. More than 90% of Topsflo pump parts and electronic components are from world-renowned brands, automotive grade electronic components, uniquely designed PCB boards, sufficient margin design for electronic solutions, low temperature rise, fast heat dissipation, The cooling effect is remarkable.

Third, the temperature range is wider. Liquid-cooled energy storage pumps must have the ability to work normally in outdoor conditions. Each Topsflo water pump has undergone strict high and low temperature fast switching tests of the whole machine, and can run stably under -40°C low temperature conditions.

Fourth, the security level is higher. The safety level of the water pump is related to the safety of the energy storage system and should not be underestimated. Topsflo pumps have six safety protections including idling protection, locked rotor protection, overcurrent protection, polarity protection, overvoltage protection, and constant power output, escorting high-efficiency liquid-cooled energy storage systems.

Fifth, the reliability is higher. The liquid-cooled energy storage system requires the water pump to have the ability to run stably for a long time, and has extremely high requirements on the reliability and stability of the water pump. Topsflo has four laboratories that meet the standards of CNAS national laboratory accreditation, equipped with international advanced testing equipment, and carries out reliability verification stricter than industry standards, and has passed CQC quality certification, CE, RoHS, REACH, WRAS, FDA, NSF and other international certifications, to provide customers with pumps with stable performance and excellent quality.

Temperature control plays a crucial role in the safety and economy of energy storage systems. As a long-term trend, liquid-cooled energy storage will have great potential. That's it for the introduction of liquid-cooled energy storage electronic water pumps. Topsflo Pump looks forward to working with more energy storage companies to jointly promote the sustainable development of the industry!