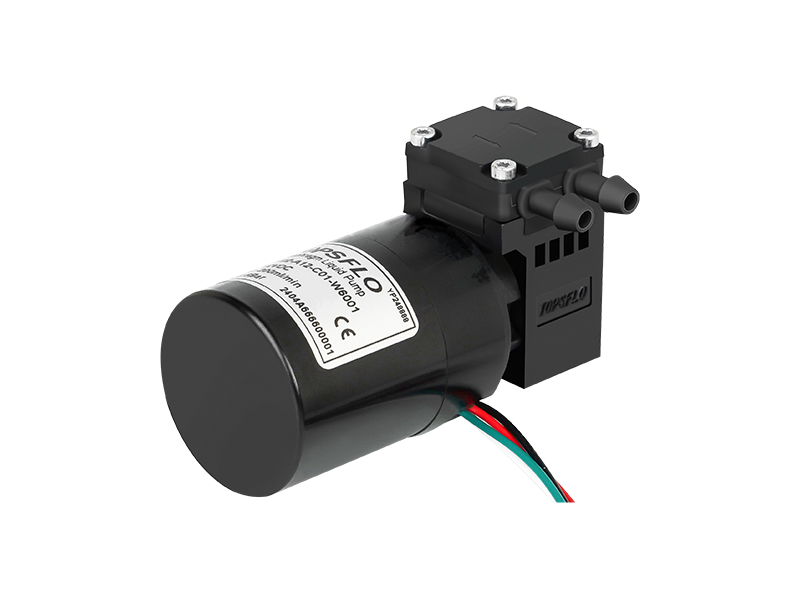

■ Overview

TOPSFLO micro diaphragm pumps and compressors are based on a simple principal,the circular power from the motor is converted into oscillating movement by aneccentric, which moves up and down its central point, this motion is then transferredto a diaphragm by means of a connecting rod, an elastic diaphragm, which inconjunction with an inlet and outlet valve creates a pumping action.

The TM 40 Series offers multiple component configurations allowing them to beused for either vacuum operation, pressure operation, or alternating vacuum andpressure operations.The innovative, compact design incorporates leading edgetechnologies that allow it to operate harder, quieter and longer, reliabler, highlyefficient.

Features:

1.Highest Performance/Size Ratio

Innovative and efficient engineering designs enable the TM30A Series to push the performance envelope in a lightweight, compact size.

2.Performs Quieter

Optimized head, chamber, and flow path reduce noise without compromising performance.

3.Lasts Reliably Longer

Using the advanced diaphragm elastomer and superior brushless motor design sets the highest benchmark for service-free operation that exceeds 10,000 hours.

4.Uncontaminated flow

no contamination of the media due to oil-free operation

5.Little vibration

Because of leading edge technologies, top quality bearing, superior brushless motor

6.High level of gas tightness

Thanks to stress-optimised structured diaphragm, newly-designed valves and sealing systems, precise placement of the pump head

7.Extreme chemical resistance

The use of chemically resistant materials optional such as FFPM, PTFE, FPM or other material combinations for the parts which allows the corrosive gas to be pumped.

8.Optimal solution for your application

A wide standard range of materials, motors , voltages configurates multiple components system selected

MODEL CODE FOR EASY ORDERING

F Motor- Coreless brushless DC motor + outer contorller, lifetime 15,000hours

(Note: other lifetime choices also available: A Motor -3000hours Premium duty brushed; C Motor, D Motor or E Motor - 15000hours coreless brushless

Application:

The versatility of TOPSFLO pumps allows a wide field of applications to be covered. Over many years our pumps have proved themselves in the following areas:

Industrial pressure and vacuum applications

Portable Analytical Instruments

Medical Diagnostic Equipment

Air Quality Sampling Monitors

Respiration Monitors

Gas or Odor Leak Detectors

The TM 40 Series offers multiple component configurations allowing them to beused for either vacuum operation, pressure operation, or alternating vacuum andpressure operations.The innovative, compact design incorporates leading edgetechnologies that allow it to operate harder, quieter and longer, reliabler, highlyefficient.

Features:

1.Highest Performance/Size Ratio

Innovative and efficient engineering designs enable the TM30A Series to push the performance envelope in a lightweight, compact size.

2.Performs Quieter

Optimized head, chamber, and flow path reduce noise without compromising performance.

3.Lasts Reliably Longer

Using the advanced diaphragm elastomer and superior brushless motor design sets the highest benchmark for service-free operation that exceeds 10,000 hours.

4.Uncontaminated flow

no contamination of the media due to oil-free operation

5.Little vibration

Because of leading edge technologies, top quality bearing, superior brushless motor

6.High level of gas tightness

Thanks to stress-optimised structured diaphragm, newly-designed valves and sealing systems, precise placement of the pump head

7.Extreme chemical resistance

The use of chemically resistant materials optional such as FFPM, PTFE, FPM or other material combinations for the parts which allows the corrosive gas to be pumped.

8.Optimal solution for your application

A wide standard range of materials, motors , voltages configurates multiple components system selected

Wetted material options:

1.Optional membrane materials:

1.Optional membrane materials:

EPDM for normal air

PTFE for corrosive air,like acid, alkali air, ozone etc.

2.Optional valve materials:

EPDM for normal air

FPM for corrosive air, like acid, alkali, ozone,etc.

MODEL CODE FOR EASY ORDERING

The model code is identical to the order number,it is made up as follows:

F Motor- Coreless brushless DC motor + outer contorller, lifetime 15,000hours

(Note: other lifetime choices also available: A Motor -3000hours Premium duty brushed; C Motor, D Motor or E Motor - 15000hours coreless brushless

Application:

The versatility of TOPSFLO pumps allows a wide field of applications to be covered. Over many years our pumps have proved themselves in the following areas:

Industrial pressure and vacuum applications

Portable Analytical Instruments

Medical Diagnostic Equipment

Air Quality Sampling Monitors

Respiration Monitors

Gas or Odor Leak Detectors

■ Specifications

| 1 | Motor Type | Brushless DC motor |

| 2 | Max flow rate | 10L/min |

| 3 | Max pressure | 250Kpa, Max vacuum:80Kpa |

| 4 | Voltage | 12V /24V |

| 5 | Ideal Life Time | 15000 Hours |

| 6 | Flow Rate Regulation | speed adjustment |

| 7 | Functions | Can dry-running, Self-priming |

| 8 | Working Mode | Continuous or Interrupt |

| 9 | Pump Theory | Diaphragm pump |

| 10 | Ambient Temperature | 41 to 158 F(5 to 70C) |

| 11 | Use Place | Indoor |

| 12 | Media: | Most Gases |

| 13 | Noise Class form 1M | 50dB /Max |

| 14 | Inlet | OD 6.5mm/ID 3.4mm |

| 15 | Outlet | OD 6.5mm/ID 3.4mm |

| 16 | Hose suggestion: | ID 5.0mm |

| 17 | Dimension | 120mm*40mm*65mm |

| 18 | Weight | 450 g |

| 19 | Materials | pump head Nylon membrane EPDM / PTFE valve EPDM / FPM |

■ Parameter

| Model | Pressure Pump | Vacuum Pump | Rated Voltage | No-load Current | Max Pressure | Max Vacuum | Max Flow |

| (Item Number) | (Item Number) | (Vdc) | (A) | (KPa) | (KPa) | (L/min) | |

| TM40-F | TM40A-F12-P25010 ( outside controller) | TM40A-F12-V8010 (outside controller) | 12 / 24 | 0.6 | 250 | -80 | 10 |

■ Curve & Dimension

.jpg)

Dimension:

■ Related products

.jpg)

.jpg)