Quality Assurance

2020-12-16

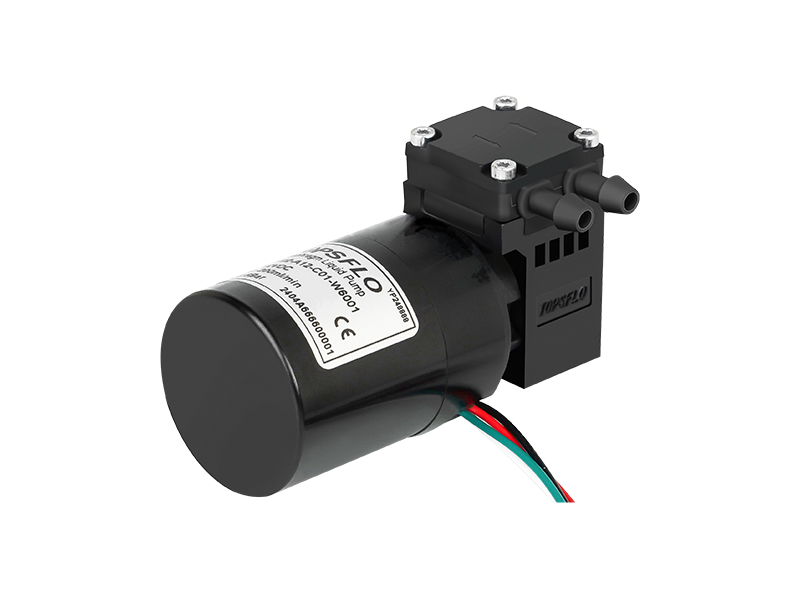

TOPSFLO has established a quality management system that is compliant to the requirements of ISO 9001. Standard processes and procedures are clearly defined to achieve customer satisfaction and to continually improve our organization’s performance. Processes in place include inspection of incoming components, component source traceability, and 100% testing of final products.

♦ We only use the finest quality materials

♦ We set a high value in simple, elegant design

♦ Our part tolerances are typically in micrometers, ensuring pump and valve performance is consistent

♦ We produce according to medical standard ISO 9001

♦ We have a clean-room according to ISO Class 7

♦ Our raw materials are 100% lot-traceable

♦ All products are 100% tested prior to shipment (test results are included with each pump)

♦ Our products and manufacturing processes follow continuous innovations 100 % our profits are reinvested in education, equipment, R&D

TOPSFLO fluidic components operate in a broad range of application environments. As a result, original equipment manufacturers may need special testing to validate their specifications. The state-of-the-art TOPSFLO test facility is equipped with the latest inspection and test equipment to perform:

• High acceleration life testing

• Serialized performance date

• Extensive environmental testing

• Sound performance testing

• Sound performance testing

• High/low Temperature testing

• Pump & motor performance testing

• Airproof testing

• Vibration testing

.jpg)

.jpg)