TOPSFLO cooling circulation pump helps the rapid development of 3D printing water cooling technology

2022-04-22

As one of the necessary office tools, printers have developed rapidly, from inkjet printers, dot matrix printers, laser printers, and now popular 3D industrial printers, with great market prospects.

The problem of heat dissipation has become a pain point in the printer industry

After using the printer for a long time, we will find that after the printer works for a long time, it is prone to the situation that the machine body becomes hot, the printing speed gradually slows down, and the work efficiency is obviously reduced.

Faced with this situation, small printers can be solved by replacing old parts, wiping the body to speed up heat dissipation, and turning it off at any time when not in use. However, some large-scale 3D industrial printers must be guaranteed to be used at any time, and on the other hand, the heat dissipation is large, maintenance is inconvenient and the cost is high, so the above methods are not applicable.

Previously, the mainstream cooling method of large industrial printers was fan cooling, because the fan cooling cost was low and it was widely used; however, it was not widely used because of its poor cooling and high noise. At present, the commonly used cooling method for large printers is quiet and efficient water cooling.

Application of water cooling and heat dissipation in industrial printers

The water-cooling heat dissipation closely attaches the water-cooling block to the heating core, and connects the micro water pump and the heat sink through the water pipe to form a complete water cycle. So as to ensure that the printer works efficiently for a long time, and there is no need to worry about the problem of the printer overheating. As the power source of the water cooling system, the micro water pump plays a key role in the cooling effect.

.jpg)

TOPSFLO effectively solves the three major problems of customers in the industrial printer industry

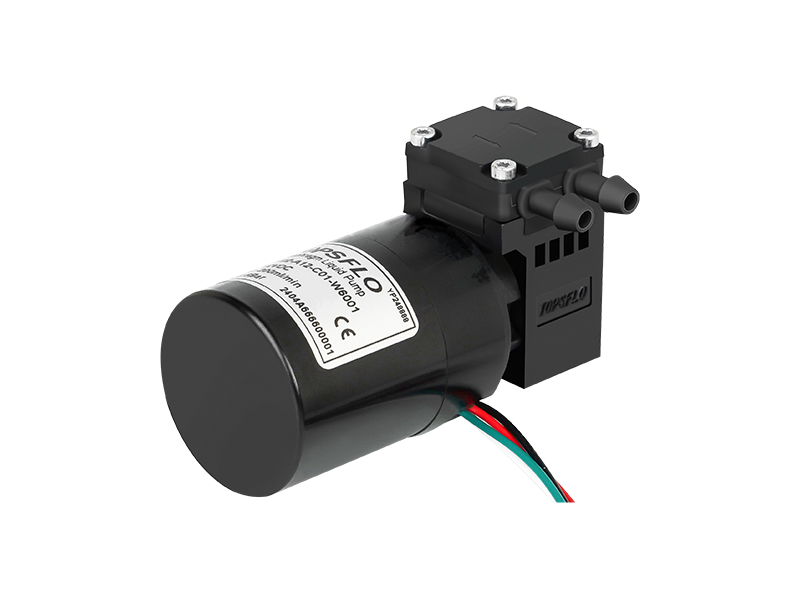

TOPSFLO pump industry has been focusing on miniature brushless DC pumps for 17 years, and has rich experience in serving large customers in the printer cooling industry. In cooperation with CN, an internationally renowned printer brand, TOPSFLO 3D printer cooling circulating water pump TL-C01 has been greatly recognized by customers.

In the customer's preliminary test, TOPSFLO TL-C01 controlled the temperature of the surface of a large extruded aluminum plate on its industrial printer by circulating coolant to reduce heat generation, effectively solving the three major problems faced by CN industrial printers at that time:

Problem 1: The cooling area of the printer is large, and the internal pipes are relatively long.

Solution: TOPSFLO 3D printer cooling water pump TL-C01 has a large water head of up to 11 meters, strong power, and can achieve large-area and long-pipe cooling very well.

Problem 2: The built-in accessories of the printer need to be small in size to save space.

Solution: TOPSFLO 3D printer water pump TL-C01 is 85.8*58mm, very small in size, does not occupy space, and reserves more design space for customers.

Problem 3: The more advanced the printer, the higher the noise requirements.

Solution: TOPSFLO micro dc water pump TL-C01 adopts patented mute design, the noise is lower than 45dB (A), to solve the customer's noise problem.

Through this test, CN has highly praised the quality and performance of the TOPSFLO 3D printer cooling water pump. The excellent working performance of TL-C01 has made the customer say that the TOPSFLO mini water pump is very suitable for the cooling system of its 3D industrial printer.

The emergence of 3D printing technology has completely changed the mode of industrial production, and the water cooling system has provided great support for the development of 3D printing technology. At present, the market demand for 3D printing technology in my country is huge. As a leader in China's micro pump industry, TOPSFLO has a consistent pursuit of quality for 17 years. We have enough confidence to help 3D industrial printers enter a new era.

.jpg)